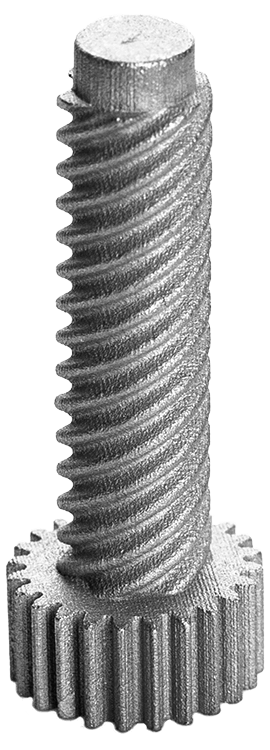

Traditional manufacturing methods often require large up-front tooling investments, are expensive at low volumes, produce excessive waste, and require long lead-times. Engineers need a rapid and cost-effective method to prototype their complex component designs. Binder jet 3D metal printing is an advanced additive manufacturing technology that uses powdered metals to build a 3D component by applying evenly distributed layers. The approach of building a part layer-by-layer gives designers ultimate flexibility because they are not reliant upon machining or tooling to form complicated geometries.

The binder jet process starts by vibrating a 10-to-20-μm metal powder onto a build platform. This layer of powder is “glued” together with an inkjet head that feeds a binder in a controlled 2D pattern. The bed of powder is lowered by 50-100 μm and a successive layer of powder is vibrated and spread onto the bed of powder, and then glued together. This is repeated until the geometry is built from successive layers.

A 1-cm-high part would consist of 100 to 200 layers of powder that are glued together. This glued part is then removed from the powder bed and the term “green” is used to describe its state. The green part is then ready to be placed in a furnace with support ceramic. The glue is removed thermally, and the geometry is sintered, shrinks, and densifies into final dimensions at temperatures as high as 1300°-1400°C depending on the alloy. Like its MIM counterpart, the 3D-printed geometry can then be treated similarly to that of a solid piece of metal: It can be worked, heat treated, and surface finished.

Printalloy®, APP’s in house binder jet 3D printing technology is used not as a replacement for metal injection molding (MIM), rather as a compliment to support the development of MIM applications.

Printalloy uses identical powder and process infrastructure associated with MIM manufacturing, without the need to build custom tooling.

| PrintAlloy® | Metal Injection Molding | |

|---|---|---|

| Investment | $0.00 | $25,000+ |

| Lead Time | Days | Weeks |

| Powder | 10-20 micron | 5-25 micron |

| Binder | Dryable liquid | Meltable polymer |

| Shape Forming | Layer by layer (50-100 micron) | Injection into custom mold |

| Debind | No | Solvent or gas phase |

| Thermal Debind and Sintering | Same | Same |

| Machinability | Same | Same |

| Heat Treat Response | Same | Same |

| Mass (g) | .1-300 | .1-300 |

| Tolerance (%) | +/-1.0 | +/-0.5 |

| Min Wall Thickness (in) | .015 | .008 |

| Surface Finish Ra (micro-inch) | 100 (xy), 200(z) | 32 |

Learn about our patented PrintAlloy® technology, material & design specifications, and more.

Download NowLearn the mechanical properties comparison between MIM and 3D Printed components.

Download NowLearn about the initial capabilities for PrintAlloy® 3D Metal Powder Printing.

Download NowSurface Finish Comparison between MIM and 3D Printed 17-4PH components.

Download NowUsing Binder Jet Metal 3D Printing to Advanced Metal Injection Molding

Download Now